YOUR GO-TO PARTNER TO ADD VALUE TO YOUR BUSINESS

Packaging Development

We support customers in innovation projects at all stages: from the initial idea to the product on the shelf

FILL GOOD'S HIGHLY SPECIALISED CONSULTING SERVICES

Thanks to the cooperation between Galdi and FILL good, we can develop the perfect combination of product, packaging and technologies, providing complete, efficient and safe packaging solutions.

Our expertise in microbiology and packaging development, combined with an in-depth knowledge of Gable Top filling processes, enables us to support our customers' innovation projects at all stages of development, from the initial idea to the product on the shelf.

Over the years, we've helped food and non-food manufacturers innovate and add value to their products with Gable Top cartons, a flexible and sustainable packaging designed to keep your product fresh and intact.

Find out more about fill Good

PACKAGING DEVELOPMENT

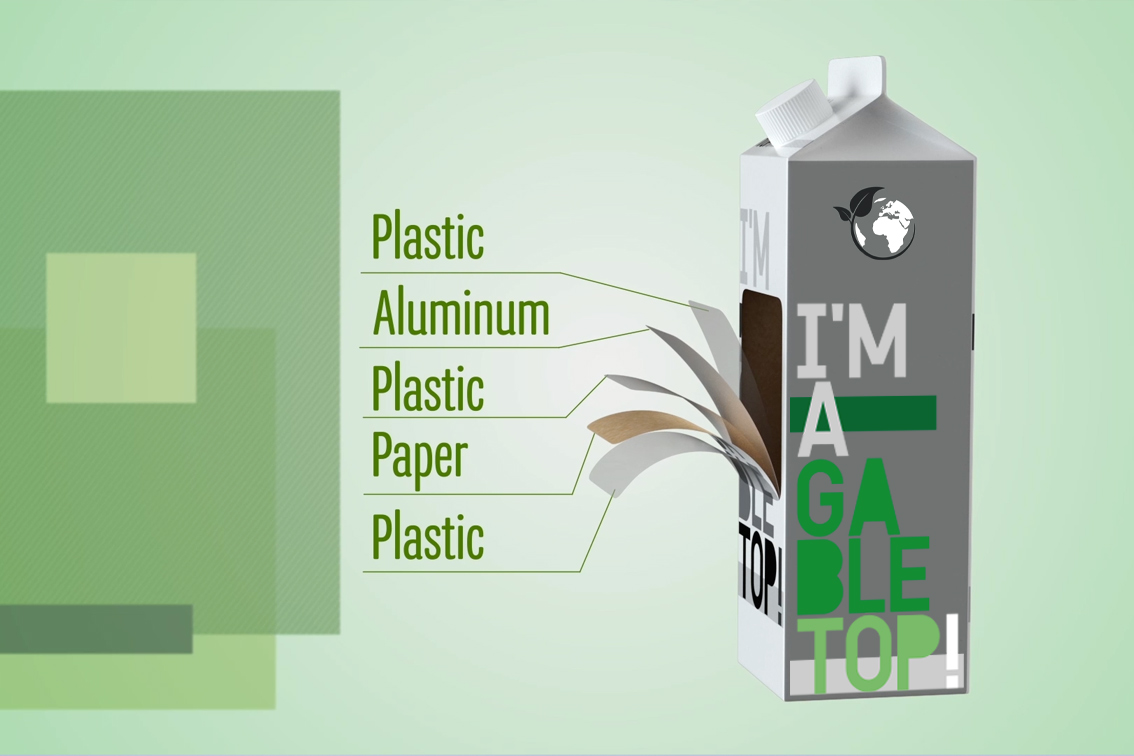

Made from 75% FSC paper, lightweight and unbreakable, Gable Tops are fully recyclable containers that optimise transport and storage, while making your product stand out on the shelf.

One of the most widely used and well-known containers in the Dairy industry, Gable Top cartons have also been used to 'dress up' other products, such as water, wine, juice, flour, breakfast cereals, as well as non-food products like detergents and personal care products.

We help customers innovate, providing dedicated consulting services to:

- Assess project feasibility quickly and effectively

- Verify compatibility of a new product or packaging solution

- Test and validate packaging solutions through machine testing

- Design and develop solutions to increase the sustainability of your packaging, like for instance the tethered closure, for which Galdi can provide already tested solutions.

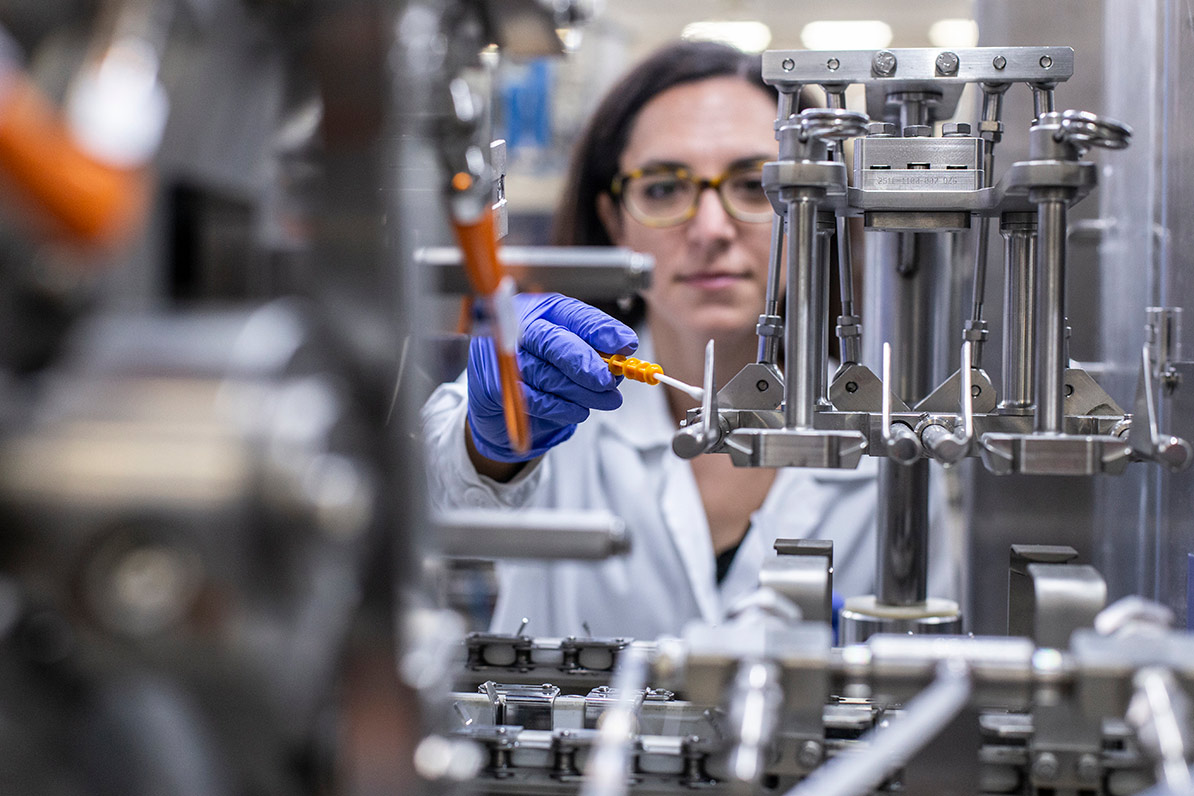

TRAINING AND CONTAMINATION

FILL good provides specialist training to ensure that operators have the knowledge and are familiar with the correct procedures to maintain hygienic conditions over time, so as to prevent and reduce the risk of contamination.

We ensure consistent food safety standards by:

- Investigating product characteristics and critical process aspects to avoid recontamination and shelf life issues

- Helping develop HACCP procedures

- Conducting sensory testing

- Designing validation protocols and shelf-life tests

- Thoroughly cleaning the filling machine prior to shipment, including ATP testing to confirm compliance with hygiene standards

- Providing fast support in the event of contamination to help troubleshoot and resolve issues quickly

SENSORY TESTING AND SHELF LIFE

We arrange organoleptic tests to assess customer satisfaction with products packed in Gable Top cartons and to detect any off-flavours or changes in taste.

FILL good also supports customers at every stage of the shelf life validation process, providing assistance with:

- Design of validation protocols and sampling plans

- Identifying the most appropriate microbiological and sensory analyses

- Support with testing and analysis of results

- Shelf-life validation with filling tests on the packaging machine

These services are particularly useful for container or closure changes (e.g. transition to aluminium-free packaging), new shelf-life requirements and when customers fill their products in Gable Top cartons for the first time.

PACKAGING-PRODUCT COMPATIBILITY TESTING

Working with the world's leading food packaging manufacturers, we have analysed and tested all types of Gable Top packaging available on the market, as well as new packaging prototypes and their suitability for packaging processes.

By testing the compatibility between product, packaging and technology, we offer customised and validated packaging systems to ensure hygiene standards and production efficiency remain consistent over time.

Paper and closure testing

Since we test and validate a wide range of closure and packaging materials and strengths, we can recommend the best packaging based on specific product characteristics and shelf-life targets.

We also support manufacturers wishing to package new products in Gable Top cartons, add new formats or update their packaging or opening system (i.e.: tethered cap).

Filling tests

We carry out packaging tests to see how products behave during the process and to determine the ideal dosing, sealing and hygiene parameters.

Several new products that we have tested over the years have been found to be compatible with the Gable Top filling process, including, to name but a few, syrups, fruit purées for cocktails and beet juice.