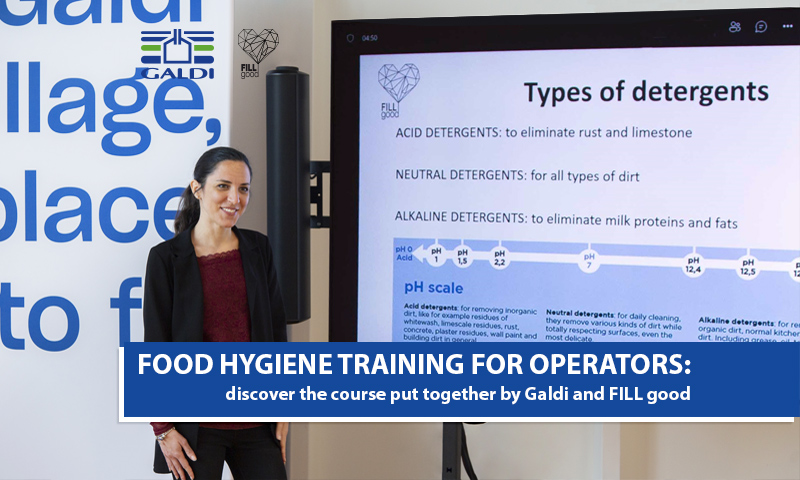

Food hygiene training for packaging machine operators

Food safety in packaging plants starts with training! Discover the course put together by Galdi and FILL good.

With a view to promoting food safety and preventing contamination incidents, Galdi makes training courses available to customers, specifically aimed at food packaging machine operators and quality managers, focused on proper hygiene practices in packaging plants.

The courses – which can be delivered both in-person and online - are run by FILL good's expert microbiologist.

The training, which takes approximately 4 hours to complete, includes:

- a 2-hour basic course;

- a 2-hour advanced course;

- plus optional practical training in the production area.

The courses provide added value because they are based on the wide variety of cases Galdi has been dealing with over the years, and on proven best practices that are fundamental to maintaining optimal hygienic conditions within your packaging facility.

FOOD HYGIENE TRAINING: TOPICS

The training covers several aspects of food safety within packaging facilities.

BASICS OF MICROBIOLOGY

Following a general introduction to the main microorganisms that are of interest to food industry operators, the course focuses on common microbial issues in food processing environments, particularly those related to the customer's specific product.

PREVENTING RE-CONTAMINATION

Based on Galdi experience, potential sources of re-contamination are reviewed, with a focus on the critical points in the customer's packaging plant. Special emphasis is placed on methods to prevent the formation of biofilm, an aggregate of microbial cells, which is a source of persistent contamination requiring aggressive treatments for eradication.

SHELF LIFE

The factors and variables that affect and reduce a product's shelf life are discussed.

TROUBLESHOOTING

Participants learn how to identify the root cause of a potential contamination incident, with the goal of preventing or resolving it as quickly as possible to reduce downtime.

SWAB TESTS

Participants are taught the most correct procedures to carry out ATP swab testing, both in the machine's filling area and in the whole production facility.

The course also includes practical training, with participants carrying out tests under the guidance of FILL good's microbiologist.

CLEANING

Participants learn how to manage CIP and SIP cleaning cycles properly.

When training takes place at the customer's premises, our microbiologist explains how to disassemble specific components and check for cleanliness while cleaning is in progress. The trainer also explains how to properly validate cleaning cycles and draft the relevant protocols.

An additional module is available upon request. Covered topics include:

- Hygienic design

- Validation of cleaning procedures

- Use of chemicals

- Detailed functioning of SIP and CIP cycles

- Regular checks using swabs or microbiological sampling.

TARGET GROUP

This training is recommended:

- For new machine operators

- Particularly for processors of delicate or extended shelf life products

- In the event of contamination incidents

- If you have recently installed a new machine or line, or if there have been any changes in the production area

The course can be useful for experienced operators too, to check whether applied procedures are correct and learn new best practices.

It is critical for manufacturers that do not have an in-house laboratory, nor dedicated staff to train operators and draft hygiene protocols, in order to maintain food safety within the packaging facility.

The purpose of the training is to transfer the necessary know-how to:

- Prevent issues that can linger over time and be difficult to get rid of

- Raise awareness of the importance of food safety among operators

- Reduce risks due to ill-informed practises

- Avoid stopping production

- Avoid having to discard or withdraw contaminated batches from the market

- Avoid additional costs for lab analysis in the event of a contamination incident

Besides training, FILL good can offer a range of additional services in the areas of microbiology and packaging development, including:

- Shelf life validation support

- Microbiological consulting services for dairy products

- Microbiological consulting services for plant-based drinks

- Specialist packaging consulting services for water in Gable Top cartons

- Cleaning and ATP tests prior to shipping

- Packaging development consulting for new products