Not only More Hygienic Filling Machines, but Food Safety as a whole

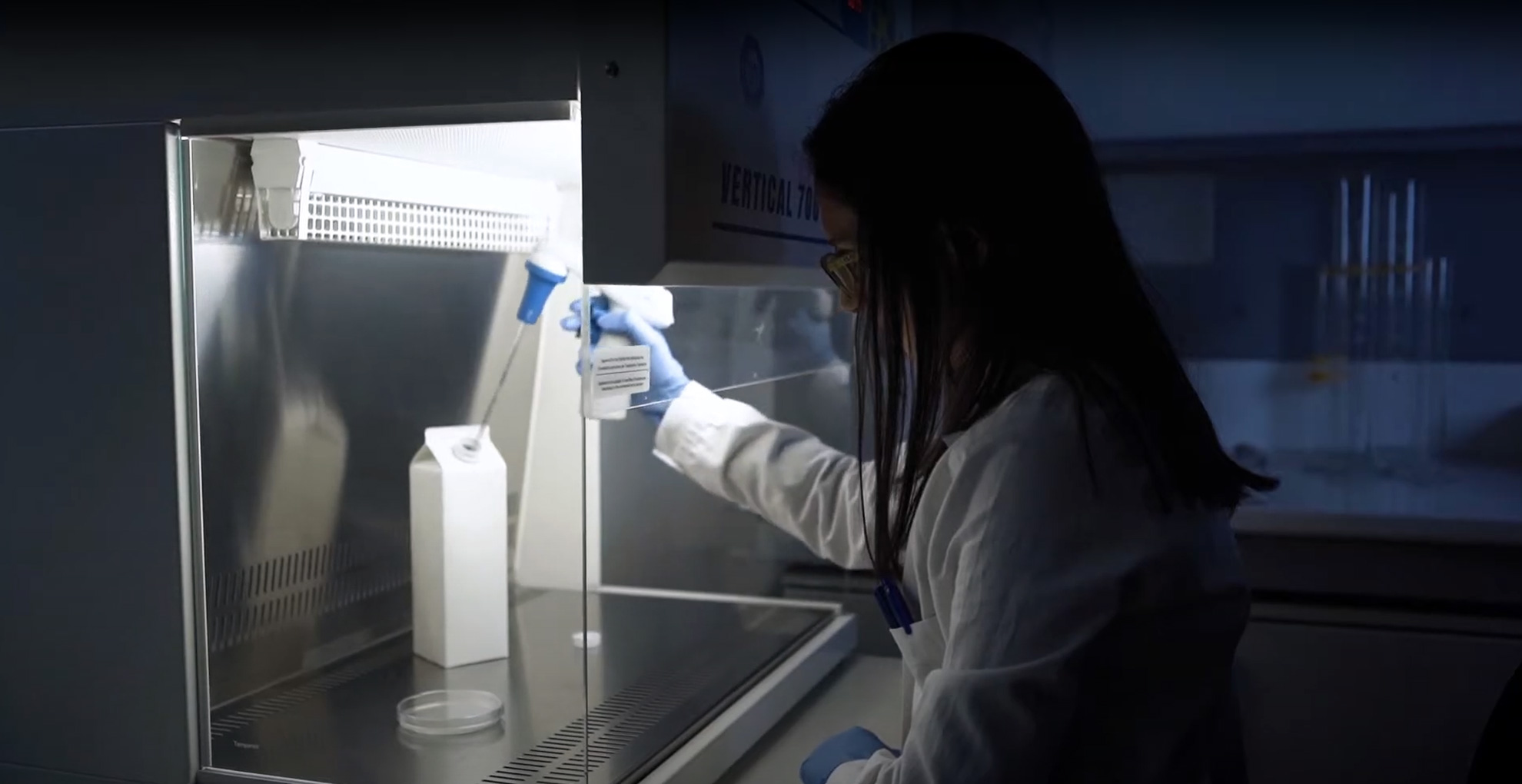

Research, testing, experimentation: Galdi deploys all its "weapons" for food safety

Our goal is not only to produce more hygienic fillers, but also to actively help our clients set up packaging plants with the highest hygienic standards and maintain them over time.

From advice on filing issues to hygienic design, from carrying out studies to conducting analyses, we aim at becoming your go-to partner for food safety, thanks to the work of our internal experts and the support of FILL good, our start-up.

HYGIENIC DESIGN

In a previous article, we discussed the importance of Hygienic Design and our design philosophy to develop microbe-proof packaging systems!

This daily, ongoing work involves designers, testers, microbiologists and technicians. It's a collective, shared challenge: each small step forward leads to big changes.

We have set ourselves ambitious goals, not only for our top-of-the-line fillers, but for all our packaging machines and systems as well.

We want to offer more hygienic fillers, but also safety. To do this, we constantly test each new solution.

Take, for example, cleaning and sanitation cycles, one of the most important components to maintain top hygienic performance levels during the packaging process.

To assess the efficiency of cleaning operations, we carry out numerous tests on:

- CIP (Cleaning In Place) – we perform swab tests to check for any organic residues. On the basis of the results, we determine correct detergent concentration, as well as the frequency and duration of cleaning cycles.

- SIP (Sanitation In Place) – we assess the effectiveness of sanitation processes and the removal of microbial load.

- External Cleaning – we test automatic cleaning cycles to make sure that critical spots inside the filler are cleaned properly.

And, of course, we invite customers to refer to cleaning instructions for procedures and timings, so that the filler maintains top hygienic standards.

Galdi recommends hygiene best practices both on the proper use of its machines and also on the processes occurring before the filling process, since in packaging plants contamination sources are often outside the machine and contamination occurs before filling the product.

If swab tests give inconsistent results, we can help the client interpret microbiological tests, to identify the source of contamination according to the type of microorganisms that were found.

HYGIENE CONSULTING

Experience and several references in Gable Top food filling solutions enable Galdi to offer clients a turnkey package. We select the most suitable filler and multi-layer carton for the product, with food safety being our top priority.

We strongly believe in sharing the skills acquired over the years with food manufacturers, exchanging know-how in view of reciprocal growth and the achievement of the best possible result.

Take, for example, the case of a bag-in-box liquid egg producer, who is very knowledgeable about the product and plastic bag filling system, and needs information on cleaning procedures for Gable Top fillers.

Or a juice manufacturer, who has been using an aseptic packaging machine for years and is not aware of the potential of Galdi machines. Or a company operating in a country where the proper maintenance of the cold chain is not always guaranteed and wishing to know what product shelf life can be achieved for their product.

In all these cases, quality or production managers can reach out to people who "speak the same language" to discuss specific issues in depth or exchange views on any validation tests – e.g. mechanical and hygienic test on a given machine.

And what about new products?

In this case, the whole team at Galdi tries to find new applications and carry out necessary tests and checks, as was the case for the water in Gable Top cartons project, the first of its kind in Italy!

We also work with our carton suppliers to test new solutions – e.g. innovative packaging material, alternative designs, new concept caps – verifying the viability of proposals through specific machine tests (mechanical bending level, welding optimisation, reaction to specific conditions).

VALIDATIONS AND TESTS

For new products or upon request, Galdi carries out the following tests:

TESTS ON FOOD (AND NON-FOOD) PRODUCTS

Tests on packaging to assess the following for each product:

- most appropriate packaging

- reactions to filling – e.g. foam production

- shelf life

- most suitable cleaning cycles

MICROBIOLOGICAL TESTS

Both internally and also relying on the support of external laboratories, Galdi carries out microbiological testing on carton-packaged food products, as well as evaluation tests on cleaning procedures.

Galdi also cooperates with the following Italian universities: Ca’ Foscari University of Venice (Department of Molecular Sciences and Nanosystems), University of Udine (Department of Agricultural and Food Sciences), and University of Bologna (Department of Agricultural and Food Sciences & Technologies).

OFF-TASTE

Internally, Galdi can rely on 20 judges to conduct blind sensory tests on a monthly basis.

The product, packaged in containers made of different materials – e.g. plastic bottle, glass, multi-layer carton or multilayer packages with different features – is classified according to olfactory and gustatory criteria, such as burning, plastic or paper smell.

ASSISTANCE AND TROUBLESHOOTING

A useful method Galdi always recommends to ensure food safety in a packaging plant is to keep an archive of tests performed by operators and of any production changes affecting:

- processes

- packaging type or supplier, as well as

- pasteuriser replacement

- any work carried out on the plant

- operator shifts

- etc.

If a contamination event occurs, this database makes troubleshooting and remote checks swifter and more effective.

To ensure that our clients receive an even faster and more effective support, for years we have been implementing a procedure for claim resolution: the exchange of know-how between experts from different departments and a database of past cases have proven decisive to solve contamination problems as quickly as possible.

We also try to think ahead, offering our clients an in-depth training covering recommended procedures to manage the entire packaging plant. Because results do not only depend on more hygienic fillers, but also on the ability to keep contaminations... outside the plant!

As we have seen, it's a collective, elaborate task.

Each single action is important to ensure food safety, which is our ultimate goal!