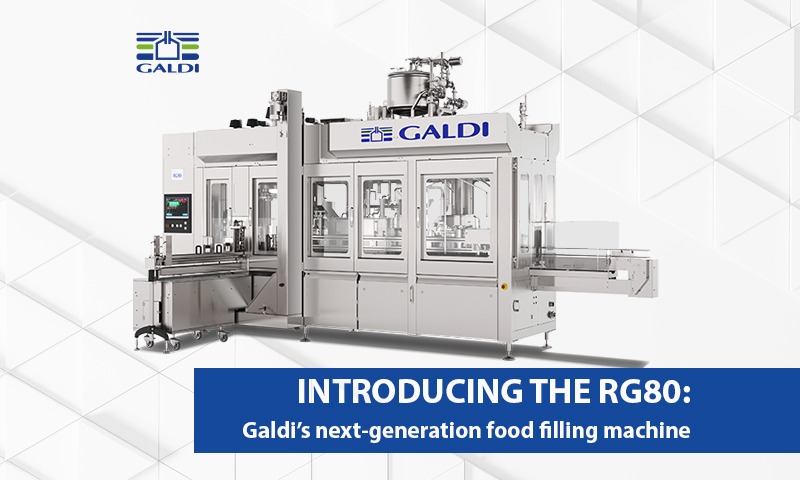

Introducing the RG80, Galdi's Next-Generation Food Filling Machine

Our "little engineering masterpiece" is next-generation in every respect, from hygiene to advanced diagnostics. It’s time to discover our RG80!

Unveiled for the first time at a digital event dedicated to liquid egg processors (watch the full video here), the RG80 is the first of a new series of next-generation filling machines developed by Galdi.

The result of years of research, the RG80 is a major technological step forward in the liquid and viscous food filling industry, particularly when it comes to delicate products (e.g. liquid egg and ESL milk).

The RG80's competitive edge lies in the combination of a cost-effective, mid-capacity (up to 3,500 cartons/hour) packaging solution with high-end features.

DISCOVER THE RG80 WATCHING THE VIDEO:

ALL THE QUALITIES OF A NEXT-GENERATION FILLER

As with all Galdi solutions, the RG80 was designed with customer needs in mind and the goal of maintaining the quality of each product.

Besides tried and tested innovations already available on our premium models, the RG80 boasts a few brand new features, developed to offer a 100% custom-built machine.

FOCUS ON THE PRODUCT

Maintaining the ideal conditions to retain nutritional and organoleptic properties throughout the packaging process is a key priority when handling delicate food products.

On the RG80, "repeatable scientific processes" - from setting filling parameters on the DDF doser to implementing the most advanced sloshing control techniques during filling and transport - ensure that product quality and hygiene are maintained. These are the result of years of research and filling tests, making up Galdi's unique know-how.

The DDF dispenser, usually available on high capacity fillers, also guarantees considerable waste reduction - both product and carton-wise - every time you start the machine.

ADVANCED HYGIENE PERFORMANCE

The RG80 was designed according to the principles of Hygienic Design, using the expertise gained with products requiring top hygienic performance levels.

And in this respect it truly is a next-generation filler!

Thanks to the work of Galdi engineers and the expert advice provided by our start-up FILL good, this new model brings together the most advanced hygienic solutions in food product packaging, including:

- Vaporized hydrogen peroxide disinfection to reduce the package's bacterial load

- Overpressure hygienic chamber and draining surface to minimise internal and external contamination risks.

- Fully automated cleaning processes to eliminate human intervention, which is a source of potential contamination

- Accurate and effective cleaning system, even in the most critical areas of the machine

Once again thanks to FILL good, we are able to offer specialist training on hygiene best practices for food filling machine operators.

HUMAN-FRIENDLY TECHNOLOGIES

The most advanced food filling machine is...the most user-friendly one!

The desire to make the RG80 even easier to use was, indeed, the main driver for development.

Frequent operations - all taking place at ground level - were reduced and simplified, as was the HMI interface, which is so intuitive that even non expert operators can use it.

In addition to a technologically advanced packaging machine, revolutionary Industry 4.0 systems also led to considerable progress in terms of diagnostics and maintenance. As "digital native" machine, the RG80 comes with a number of advanced sensors, as well as analysis and monitoring devices (e.g.: MaSH). Combined with Galdi's new digital assistance services, they enable to:

- speed up and improve troubleshooting

- predict problems, even before the operator becomes aware of them!

- provide a comprehensive overview of your machine's status

- facilitate prompt intervention remotely

All this translates into a substantial reduction in downtimes and faster troubleshooting, and therefore more stable production, with your machine always running at top performance levels.

VERSATILITY AND PRECISION

Versatility when it comes to format, product and paper type: this is the hallmark of all Galdi Gable-Top fillers and one of their key strengths compared with other systems (e.g Roll Fed packaging).

The same filler can handle different formats (e.g. 250ml, 330ml, 500ml, 750ml and 1000ml). Format changeover takes less than 3 minutes and you can rely on the accuracy of the bottom and top sealing system, which is crucial for product shelf life too.

Moreover, thanks to the DDF dispenser, you can pack products with different viscosity, also containing fibres or small pieces, while maintaining product quality and filling performance levels unchanged.

Finally, Galdi fillers can handle all paper types supplied by the world's leading packaging manufacturers.

GALDI'S SUPPORT

Besides top performance, our next-generation filler today comes with a range of additional services, as Galdi aims to be with you every step of the way: from the time you choose the package until the product is ready for dispatch.

Thanks to newly acquired resources, Galdi has been able to position itself as a Solution Provider offering comprehensive service and packaging solutions:

- training and consulting services in the fields of microbiology and package development, thanks to our start-up FILL good

- complete packaging line development

- production area layout planning and seamless system integration

- selection of and coordination with the world's leading food packaging manufacturers, as well as processing and pasteurisation machinery suppliers

The RG80 - our next-generation food filling machine - marks the beginning of a new era at Galdi. Our values remain the same, but our customers can now benefit from new resources and even more support!

Would you like to find out more about the RG80 or discover Galdi's world?