A Comprehensive Filling Experience

In order to optimize the filling process, the process line must be taken into account as a whole

Offering highly efficient technology solutions for the whole process line is the approach behind Galdi pre-sale and after-sale consultancy services, as well as the reason of our recent acquisition of Artema Pack, specialized in end-of-line packaging machines.

THE IMPORTANCE OF LOOKING AT THE WHOLE PROCESS LINE

Purchasing a cutting-edge filler will be pointless if the end-of-line phase is underestimated. At the same time, it makes no sense to focus on the right product packaging while ignoring the final packing.

In fact, packaging requires an integrated approach in order to meet the characteristics of the packaged product as well as production requirements. Such an approach allows maintaining production, quality and efficiency standards unaltered throughout the whole line.

The same applies to distribution, where end-of-line packaging plays an important part not only for product safety but also brand perception.

INTEGRATED FILLERS AND PACKAGING MACHINES

The integrated design of the entire production line brings significant benefits:

- More stable MME and OEE in the short and long term

- Coordinated filling and packaging operations

- Maximum optimization of the production area

- Quicker and safer installation and set-up

- Better integration among machine systems

When filling and packaging machines work together and with the same efficiency, the worst nightmare of every production manager -- the worrying sound of the downtime alarm -- is also dispelled.

Today, with the acquisition of Artema Pack technologies, we are delighted to offer our clients even higher chances of success.

ARTEMA PACK END-OF-LINE PACKAGING MACHINES

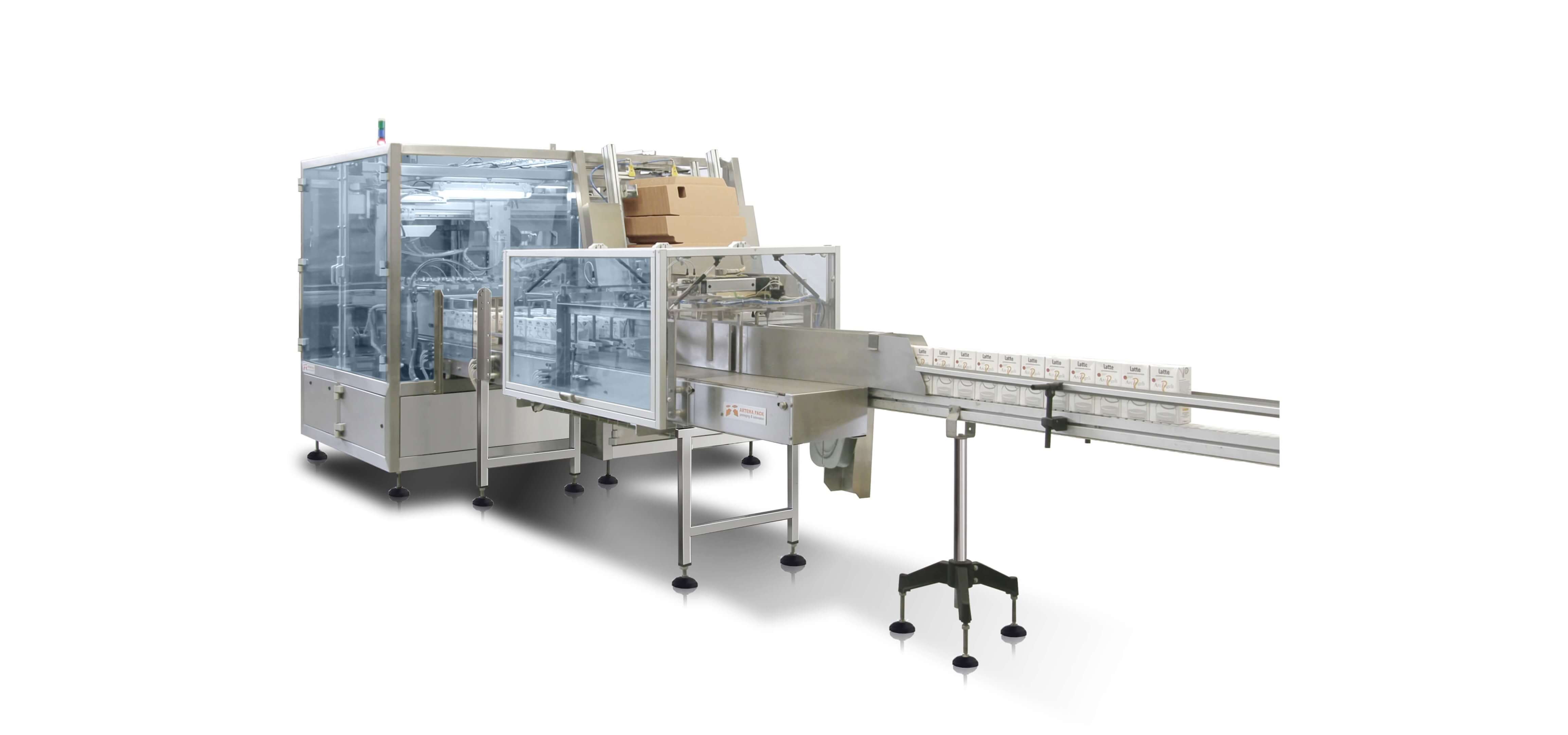

Thanks to its 30-year-long experience, Artema Pack has developed a series of end-of-line automation and packaging systems for an extensive range of products and packages (Gable Top milk cartons, fruit juice bricks, dry foods, etc.).

From shrink film wrappers to wrap-around and American Box case packers, every machine has been designed to simplify and optimize operations.

This is the key factor shared by Artema Pack packaging machines and Galdi fillers: meeting our clients’ requirements with cost-effective and time-saving solutions for maximum productivity.

This approach involves all our processes, from design to consultancy.

GALDI: YOUR FILLING PROCESS CONSULTANT

Similarly, the new expertise acquired with Artema Pack perfectly matches the process know-how developed by Galdi over the years.

Today, Galdi can offer advice and technology solutions for the entire process line.

Our services are intended for food producers wishing to start off on the right foot, as well as for established plant owners willing to make their filling and packing processes more efficient.

Learn more about how to optimize the various packing processes.

To receive first-hand information, contact us.