Optimal user experience thanks to digital solutions!

Galdi packaging machines are easy to start, use and configure. Explore the new digital features for improved usability and productivity!

Galdi's goal is to design and manufacture packaging machines that are easy to use and can simplify life for our customers.

In terms of hardware, Galdi machines are developed to guarantee optimised usability and simplified maintenance. In addition to that, digital technology is opening up new solutions that help operators and maintenance staff in their daily work.

The latest digital and automation implementations are designed to streamline processes, minimising the risk of human error, while providing an improved user experience and usability.

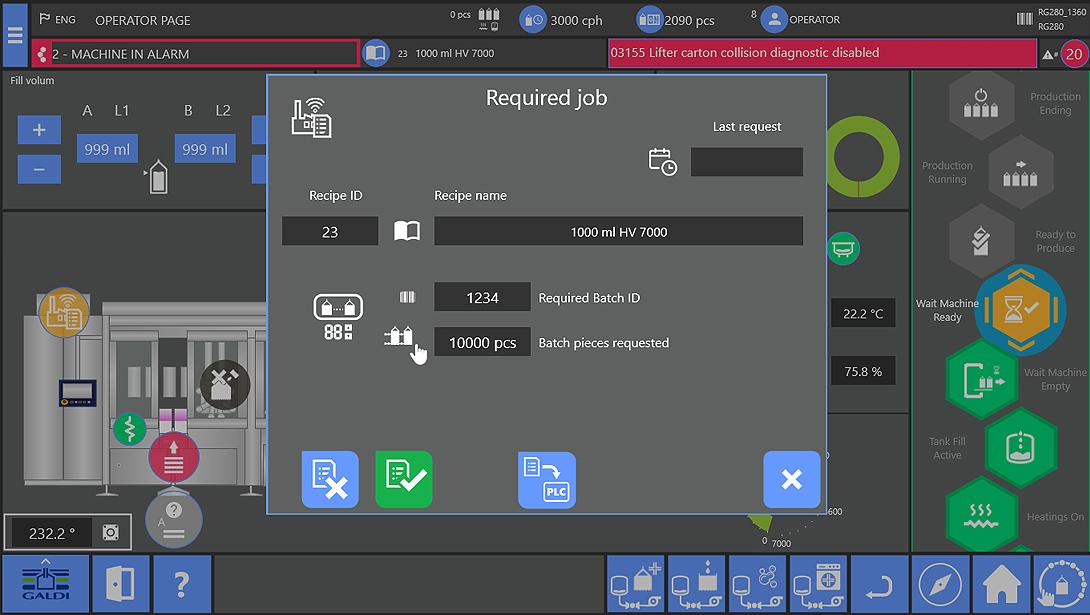

Improved wizard mode for operators

The new HMI interface on Galdi packaging machines comes with an advanced and user-friendly wizard mode that assists operators with guided procedures, displaying supported actions, and providing warnings and helpful information.

Using push buttons, operators can easily and intuitively follow instructions and perform necessary tasks step-by-step, safely and efficiently.

Through guided navigation, the following stages can be optimised:

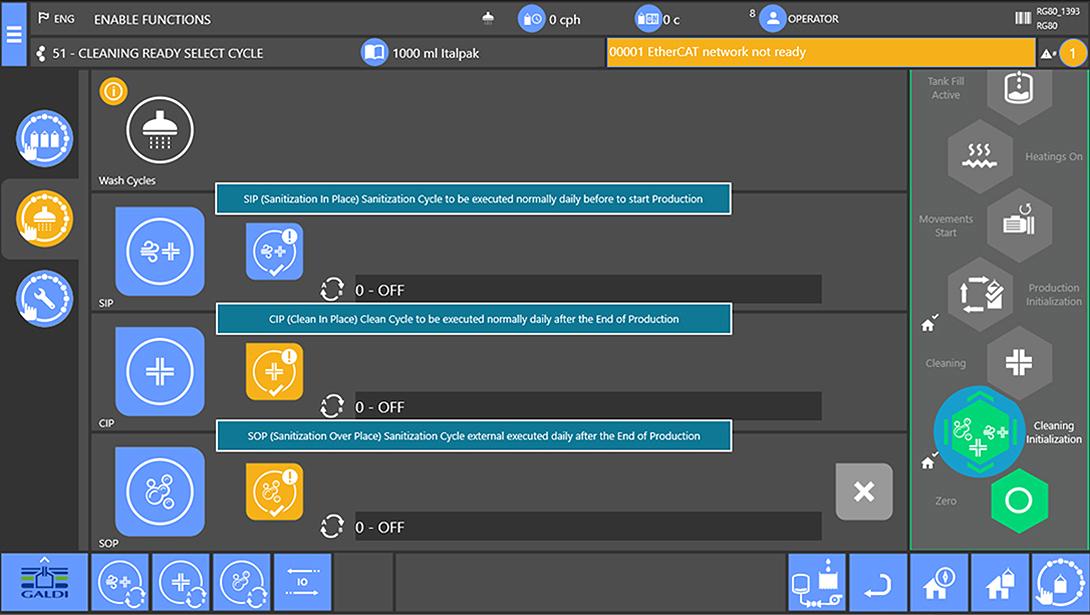

- Cleaning and Sanitisation: the operator is prompted to select the cleaning cycle and the correct sequence is shown on screen.

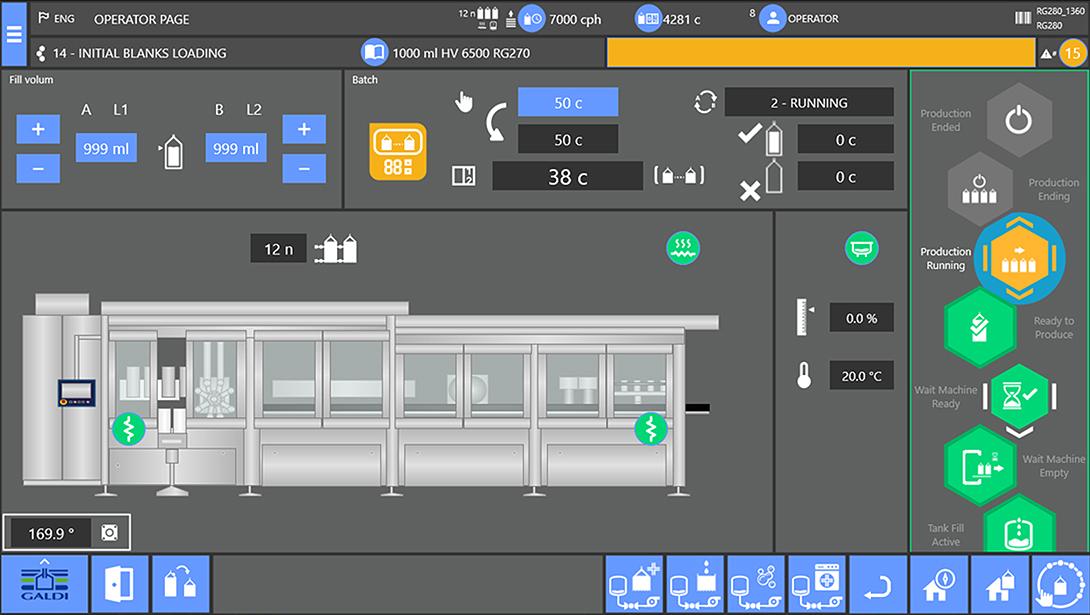

- Preparing for production: the operator performs all required steps to get the machine ready for production. S/he can enter the number of cartons (batch), set up the start time and also an automatic stop based on the entered batch quantity.

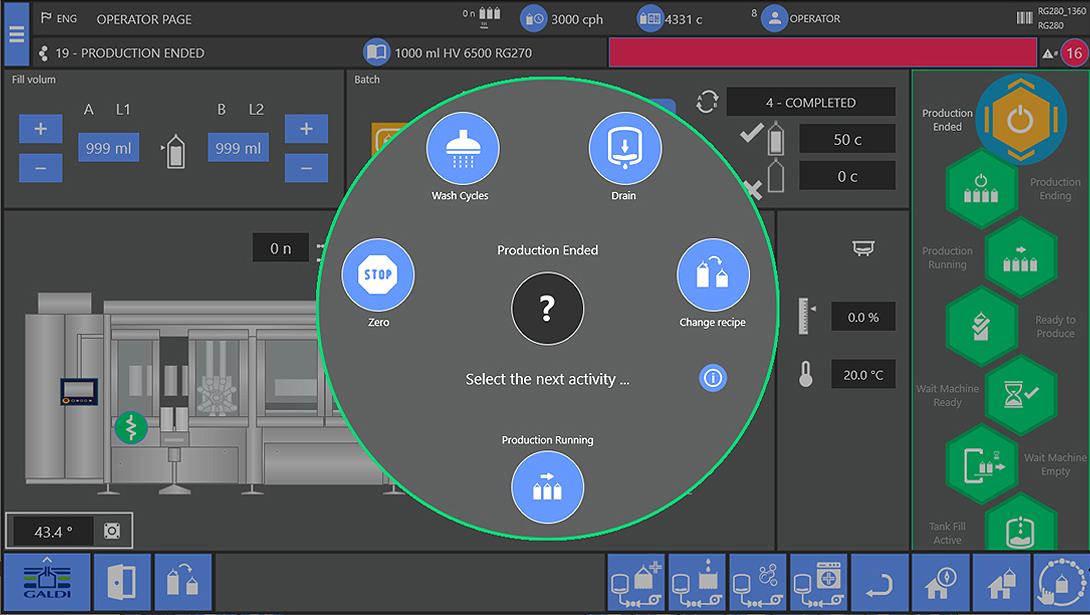

- Production end: the navigation display shows available tasks, depending on your production plan (e.g.: starting the cleaning process, changing recipe/paper/format while keeping the same product, shutting down the machine, restarting production, etc.).

The benefits for individual users

Besides simplifying life for operators, the new HMI is also designed to ensure an efficient user experience for all users, from production managers to maintenance technicians.

From the customer's point of view, this means:

- Improved autonomy and greater efficiency when operating the machine

- Optimised and more stable production performance, regardless of the operator assigned to the machine

- Reduction of daily and major machine downtime

- Improved machine use, resulting in better performance over time and reduced TCO.

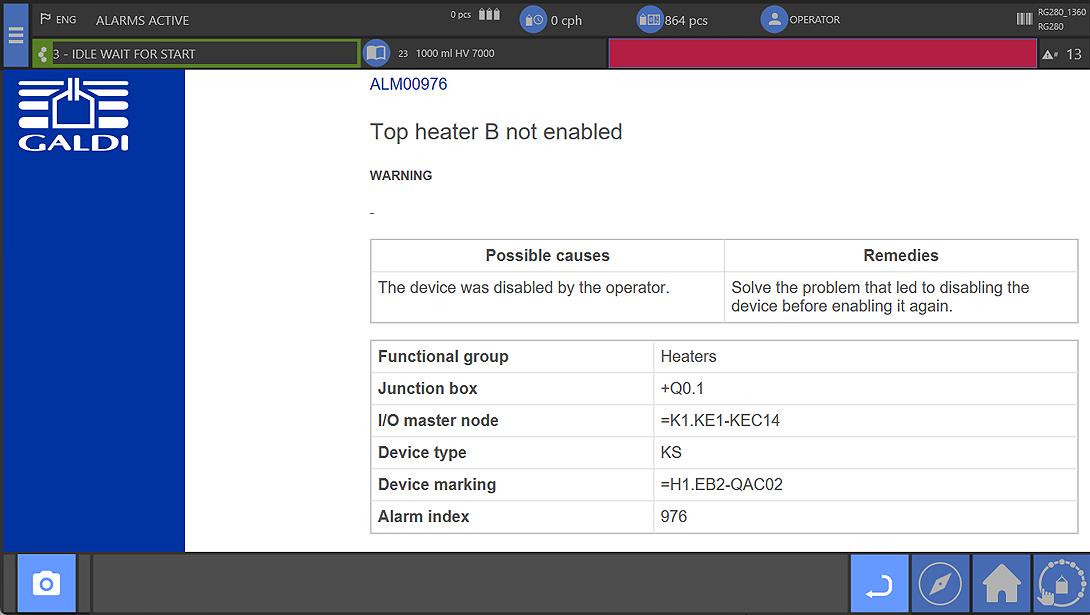

Troubleshooting and assisted maintenance with Help Mode

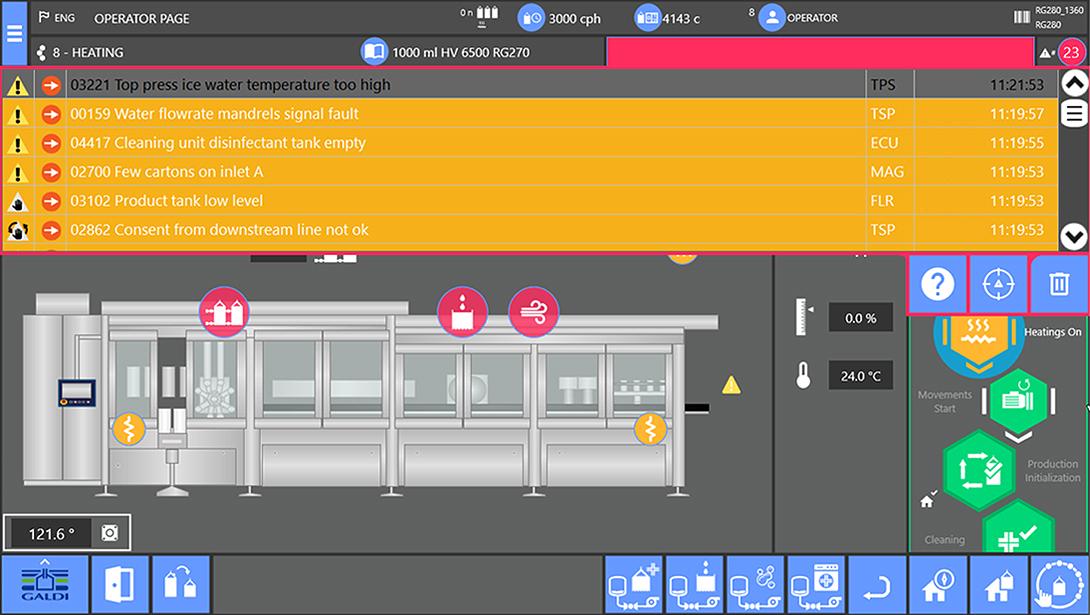

The HMI also plays a key role in troubleshooting and maintenance support.

The system itself detects and reports malfunctions and potential problem areas before expert intervention is required.

This is possible through the latest innovations we introduced in our digital native machines. Besides being equipped with advanced sensors, these systems can process data and warnings, returning valuable information.

The packaging machine's panel assists operators and maintenance technicians in troubleshooting and maintenance operations via the advanced Help mode, which simplifies and reduces the time needed for troubleshooting.

When assistance by a Galdi technician is needed, experts can help remotely in real time, further reducing production downtime.

To get a comprehensive assessment of the condition of the machine and to anticipate downtime, the MaSH monitoring system developed by Galdi can be also activated on your packaging machine.

Automated recipe changeover

Another tool to improve user experience and simplify work for operators is the automated recipe changeover.

A dedicated Galdi team developed the solution, also based on customer feedback, to guarantee the following:

- A fully automated process that can be managed remotely

- Integrated with ERP and MES systems

- Configured according to internal procedures

Interacting with the factory, the system displays the steps the operator should take.

Additionally, the system continuously monitors performance, also simplifying work for production managers.

What's next? The automated remote recipe changeover for the entire line!